Tags

#coding

#electronics

#microCode

Embedded programming

- Environmental monitoring with online data logging to Thingsv

- Grow monitors | What watches the watchers?

- LCD x Arduino

- Programming "Hello to the World" with C

- Breathing light : An arduino experiment

- Datasheet Atmel ATtiny24/44/84

- Echo : Programming.c

- Programming a programmer

- Arduino IDE, introduction

2017 Apr 06

#coding

#electronics

#microCode

I tested the effectiveness of my build with a C program written by Neil Gershenfeld.

The contents of the make file are mostly the same as my previous ATtiny44 board. Because I used the same resonator, the timing fuses are the same. Only the name of the C accompaning C file has changed. Create the hex and out files.

make -f hello.LCD.44.make

Using my FabISP...

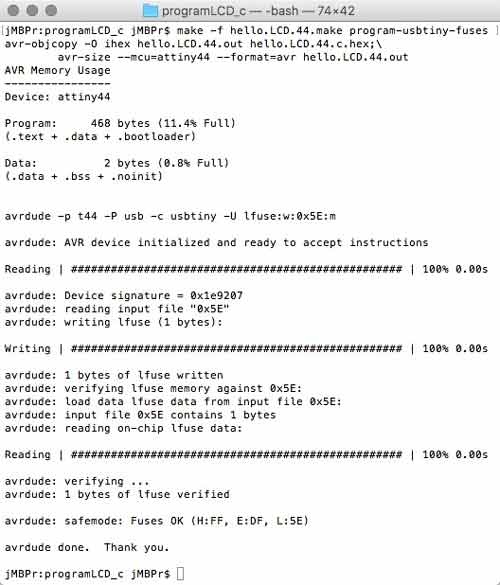

make -f hello.LCD.44.make program-usbtiny-fuses

and then send the program...

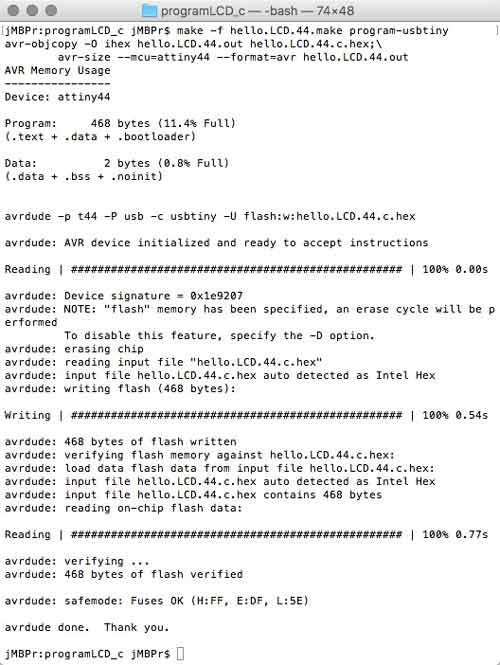

make -f hello.LCD.44.make program-usbtiny

This feels good.

Download project files

Share this post...

« Previous post :: Fabricating a gestalt stage

After much intense strategic consternation, we decided to begin our project by developing through the Gestalt framework. The framework is developed; we are beginners. Can we connect rotary stages on either side of a linear stage equipped with a brush effector? The idea is similar to a common CNC machine. Wheels mobilize the whole assembly along an infinite X axis. A stage holding an effector moves a limited distance between two wheels (Y). The effector moves a minimal distance along the Z axis. The first step is to fabricate a linear stage. Download the Rhinoceros file and you may need...

Next post :: LCD ATTiny44 PCB »

I am using a Lumex 16*2 character LCD Module. This LCD only requires 5v and six data pins to get up and running. I do not have a PCB with the free pins or proper configuration to use with this LCD. Not a problem however, because I have learned my way around designing, milling and stuffing PCBs. Get it. I started by inspecting Neil Gershenfeld's example LCD board. I posted a low resolution copy of the image here for convenient reference. The linked version is better. While following this is great for a beginner like me, I quickly became aware...