Tags

Pure Imagination

- Environmental monitoring with online data logging to Thingsv

- Inventory

- Hessian/ burlap/ crocus composites

- CNC milled wood frame

- Grow monitors | What watches the watchers?

- Grow module | Design and fabrication

- Grow Module | The science

- Processing Light Graph

- Milling a composite mold

- Composites : Modular growth, testing

- Bio-electro-chemistry

- Bioelectrochemical testing pod

- LCD x Arduino

- Precedents

- Discussion

- Design, Materials and Methods

- History : Early concepts

Background

I have a vision of bio/technologically literate people who live in symbiosis with nature and machines. Their living vessels harvest and provide electricity, water, food, clean air, and comfort. In exchange, these people do people stuff: breathe, wash clothing/ dishes, excrete things and their vessels love them for it…

On my journey to resolve this vision, I would like to investigate low-cost biological approaches for energy production. That starts with the Sun. The Sun is the ultimate source of energy for almost all life on Earth. Solar energy is carbon-free, everywhere, and abundant. Nature demonstrates the potentials by utilizing solar energy through the process of photosynthesis. Indeed, that potential has been developed into a number of synthetic techniques, i.e. solar cells, to emulate photosynthesis to generate electricity, often to greater efficiencies. One branch of this research seeks to develop similarly efficient light harvesting bioelectrochemical processes replete with interesting advantages over synthetic approaches in that the photosensitive components are assembled and maintained by living organisms that self-repair, reproduce and store energy for power generation in times without sunlight. Among the forms this research has taken is biophotovoltaic devices, i.e. algae based solar panels, and microbial fuel cells. "Life depends on the transfer of electrons between different biochemical intermediates to discharge or capture energy, or drive chemical change. The ability of certain microbes to facilitate the direct and/or indirect transfer of electrons outside of the cell (exoelectrogenic activity), which can then be harvested for reductive power, has driven the development of a variety of devices in which living organisms directly generate electrical power, which may also be coupled to separate reductive processes in the devices (collectively known as bioelectrochemical systems)." -Energy Environ. Sci., 2015, 8, 1092. Exoelectrogens metabolize organic substrates (released by the plants) and donate electrons to conductive materials (ie electrodes). The captured electrons are then directed through an electrical circuit to reduce an electron acceptor (i.e. O2) in the cathodic region and used to power pocket devices, mochas and other critical human things.

A subset of plant-based bioelectrochemical processes utilizes nonvascular bryophytes, poikilohydric plants with a superior tolerance to dehydration and survivability in a wide range of temperatures and habitats. Further, bryophytes provide a source of food for a microbial consortia, including exoelectrogenic microbes, and influence carbon and nitrogen cycling in the atmosphere. The first bryophyte microbial fuel cell, based on the forest moss Dicranum montanum, was reported at the First International Plant Power Symposium in Ghent, Belgium in 2011.

Okay, I should probably discuss the importance of gardens here later. For now, you and I can agree, gardens are magical.

Pure Imagination posts...

- Environmental monitoring with online data logging to Thingsv | 2018 Mar 31 | 14 minute read

- Inventory | 2017 Jun 28 | 1 minute read

- Hessian/ burlap/ crocus composites | 2017 Jun 28 | 2 minute read

- CNC milled wood frame | 2017 Jun 28 | 5 minute read

- Grow monitors | What watches the watchers? | 2017 Jun 14 | 9 minute read

- Grow module | Design and fabrication | 2017 Jun 13 | 7 minute read

- Grow Module | The science | 2017 May 31 | 4 minute read

- Processing Light Graph | 2017 May 24 | 8 minute read

- Milling a composite mold | 2017 May 12 | 8 minute read

- Composites : Modular growth, testing | 2017 May 09 | 2 minute read

- Bio-electro-chemistry | 2017 May 03 | 3 minute read

- Bioelectrochemical testing pod | 2017 Apr 25 | 1 minute read

- LCD x Arduino | 2017 Apr 06 | 2 minute read

- Precedents | 2017 Mar 10 | 1 minute read

- Discussion | 2017 Feb 10 | 1 minute read

- Design, Materials and Methods | 2017 Feb 08 | 3 minute read

- History : Early concepts | 2017 Feb 01 | 2 minute read

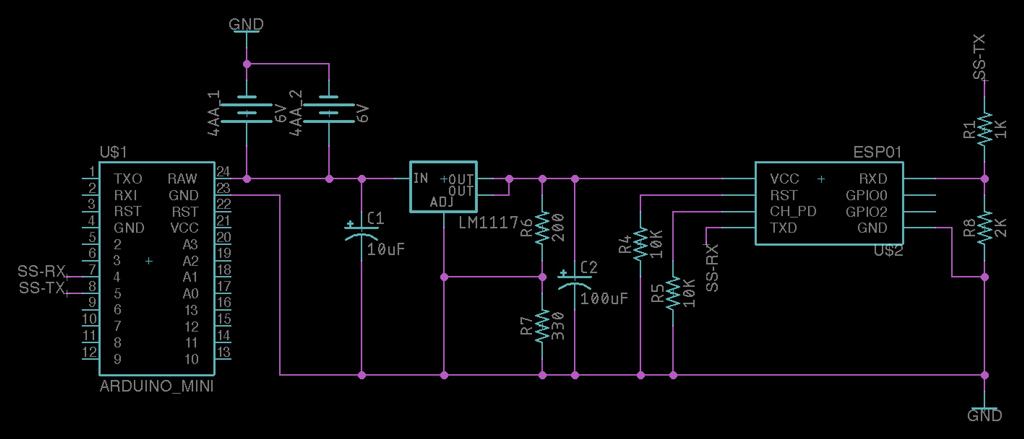

Over the past few months, I have continued to develop the electronics and programming aspects of this project. I now have a system for evualating power potential and environmental sensing, and logging all that data online to Things Speak, an open Internet of Things Platform. Previous to using Things Speak, I was logging data to an SD card. However, with an SD card, I need to periodically pull the data from the card. Extra work. Using Things Speak, the data is available to me and everyone else instantly, everywhere. There have been some issues with wifi stability and internet connectivity...

Following is a list of prices and quantities for the second prototype Pure Imagination build. Many of the materials, ie. acrylic, electronics were donated to the project from the fablab, others as part of the Fab Academy inventory/ session resources. For those materials, I checked online sources. The most expensive parts of the build are the chemical components and, shockingly, the silicone for the concrete mold. The silicone mold survives however, and that price would "decrease" with each successive cast. The bioelectrochemical system needs to be optimized for electricity output and material cost, perhaps alternative materials could be found for...

To make the composite surface, I will combine hessian with a two-part resin which takes about thirty minutes to set and five hours to cure. This job is messy business and I did not have gloves or time to get gloves. That was a bad idea, first, not many photos. Second, the resin gets very hot in just a few minutes, trial by fire. Finally, it is nearly impossible to get off your hands. After countless soapings, I resorted to scrubbing my hands with coarse hair brush/ soap combo and then wearing (different) gloves for the next few hours because...

I would like to use 2 dimensional milling to cut a wood frame to carry the concrete grow modules and hide the electronics. There will be a small cut-out on one side for an LCD which will be displaying data coming from sensors across the system. The concrete casting process was not precise due to some flexure in the walls of the mold. Each module has an extra 4-5mm total width in both directions. So the first part of making the frame was to compensate for this error. I should note, I kind of like the little bit of error...

Simultaneous to the module development, I will produce some grow module monitoring equipment. Previously, I worked with a phototransistor sensor, an LCD output and wrote a basic graphical interface for live monitoring the phototransistor readings. Today, my goal is to combine these with voltage sensoring so I can begin tracking the correlation between sunlight and power generation in the bioelectrochemical testing modules. Starting with a little research, I found that by simply connecting an input voltage to an open ADC pin, I could take voltage readings. Duh. I have been doing this for weeks via the phototransistor. I returned to...

My idea is to first create a small modular testing garden. I began with some sketches on paper and Rhinoceros. The bioelectrochemical modules are red and the frame is purple. I think this way will be able to be broken down and assembled easily and can be grown or reduced by adjusting the array. While the sketch shows a six by six array, I might reduce it to five by five. The testing modules were essentially cubes. This module is has a smaller bottom half to create a lip for sitting on the structure. In the upper portion there is...

The nonvascular bryophyte microbial fuel cell operates in two main zones: anode and cathode. The anode side is a layer of moss, two mixtures of cotton and carbon (10:1, cotton : carbon weight) sandwiching a single layer of stainless steel mesh (as thin as possible). This anode mixture is from the 2016 October 3 Royal Society published work of Paolo Bombelli, et al. Electrical output of bryophyte microbial fuel cell systems is sufficient to power a radio or an environmental sensor. The cathode is a sandwich of acrylic (bread), rubber (condiment), hydrogen electrode (10 wt % Pt/C + 5% Nafion...

Enough with the tutorials. Now I would like to start putting these together with some kind of simple visual or audio interface connected to sensor readings. I started by looking at this former Fab Academy student's work mapping phototransistor settings to a dynamically configurable 3D model. He was able to combine sensor readings from arduino with a Processing sketch from Open Processing Org, a wonderful place for sharing processing sketches. I went there with the intention to grab a sketch, however I was a little overwhelmed so instead I started looking at former Fab Academy students' pages for a sketch...

I am preparing a mold of four parts: two outside halves and two inside halves. Then I plan to make a burlap plus resin composite surface around the two inner halves. Finally, I use the outer halves to compress the composite as it cures. I have yet to try milling multiple surfaces from one block of material. Well, until today. The inner halves each require milling on two sides of the material. I sized the molds to the constraints of our lab's Roland MDX-40A benchtop CNC machine. The XY maxes are 305mm according to the manual. Z max is dependant...

Composite materials are made of two or more constituent materials, each with significantly different, yet complimentary, physical and or chemical characteristics. When combined into a composite, the team of materials is greater than the sum of its components. I started the project by mocking up a form in Autodesk Maya. The form is like bamboo in that it grows in sections and has openings to contain the moss. At this point, rather than spending much time modeling this object, I would like to jump into making composites becasue it is my first time. This is a little mockup of what...

The fabrication demands of this project are far less than other aspects. Keep it simple. Spiral develop. I essentially want an open-faced cube in acrylic. I will develop a grasshopper, parametric model with variables for overall dimensions, finger joint size, laser kerf, bolt and other holes (unrelated to box adhesion). The prototype is based on the work of Paolo Bombelli, et al. This is the desired composition. The pot, plastic fixture and possibly rubber washers will be laser cut and Jakob Skote's Moss Powered Wifi Jammer project. Excellent work. Visit them. Fast-forward a little in time and I have a...

I would like to begin prototyping grow modules for Pure Imagination. The first challenge is setting up a plant microbial fuel cell system for generating electricity with moss. This work will heavily rely on the scientific research from Paolo Bombelli, et al. I thought I could cast this pot... ...and thinking how to do that with ooloo is tough. I think slip casting or vacuum forming would be the easiest route. I have experience vacuum forming and more, and would have some concern with the finishing that would need to be done after pulling a form for this object. If...

Arduino has a built in libary, "LiquidCrystal.h", for programming this type of LCD. I thought it would be fun to imagine a prototype of HAL 9000 prior to artificial intelligence using the LCD display to communicate and the LED to hint life. Arduino IDE is packaged with many sketches of LCD functions. Browse to File > Examples > LiquidCrystal and you can check those out. First, write in the sketch the command to send the library for the LCD. #include <LiquidCrystal.h> Then, you need to dictate which MCU pins are connected to the RS, E, DB4-7 pins of the LCD...

Most of the science I used comes from Dr. Paolo Bombelli's excellent research in the field of bioelectrochemical processes. This includes his published research: Electrical output of bryophyte microbial fuel cell systems is sufficient to power a radio or an environmental sensor and Biophotovoltaics: oxygenic photosynthetic organisms in the world of bioelectrochemical systems and Biophotovoltaics: Energy from Algae published in Catalyst Vol 21 #4, April 2011. Alex Driver and Carlos Peralta's collaboration with Dr. Bombelli Moss Table. In a series of collaborations, they were able to run environmental sensors and a small LCD display for two weeks uninterrupted and operate...

Michael Reynolds : Earthship Biotecture Primavera de Filippi's Plantoid introduction.

I would like to build a small moss (dominate) garden which has an electrical outlet of a contrasting color to green sitting on a small pole in the center. The electrical outlet is connected to a battery that is hidden in the base. The moss is organized in power modules which are connected and charging the battery. When something small is connected to the electrical outlet, the battery discharges electricity. The whole garden can be dissambled and reassembled with relative ease. A secondary objective is to make (most likely) independently powered monitoring equipment (lux, temperature, humidity, soil moisture, watt output)...

2017.2.1 My ambition is to make an energy harvesting system using biological photovoltaics as an exhibition work to bring attention to clean, sensational possibilites for sourcing energy and the fact that we need [wildness] nature more than it needs humans. This system will be a network of modular components. Each module consists of a fabricated shell, preferrably from cradle-to-cradle capable materials, biological material (plant or algae, tbd), energy harvesting materials, bio-support materials. The network is connected to an energy storage and MCU. The MCU can be used for monitoring illuminance, humidity, temperature and volt output statistics to be used in...