Tags

#model3d

#pureImagination

#CAD

Pure Imagination

- Environmental monitoring with online data logging to Thingsv

- Inventory

- Hessian/ burlap/ crocus composites

- CNC milled wood frame

- Grow monitors | What watches the watchers?

- Grow module | Design and fabrication

- Grow Module | The science

- Processing Light Graph

- Milling a composite mold

- Composites : Modular growth, testing

- Bio-electro-chemistry

- Bioelectrochemical testing pod

- LCD x Arduino

- Precedents

- Discussion

- Design, Materials and Methods

- History : Early concepts

2017 Apr 25

#model3d

#pureImagination

#CAD

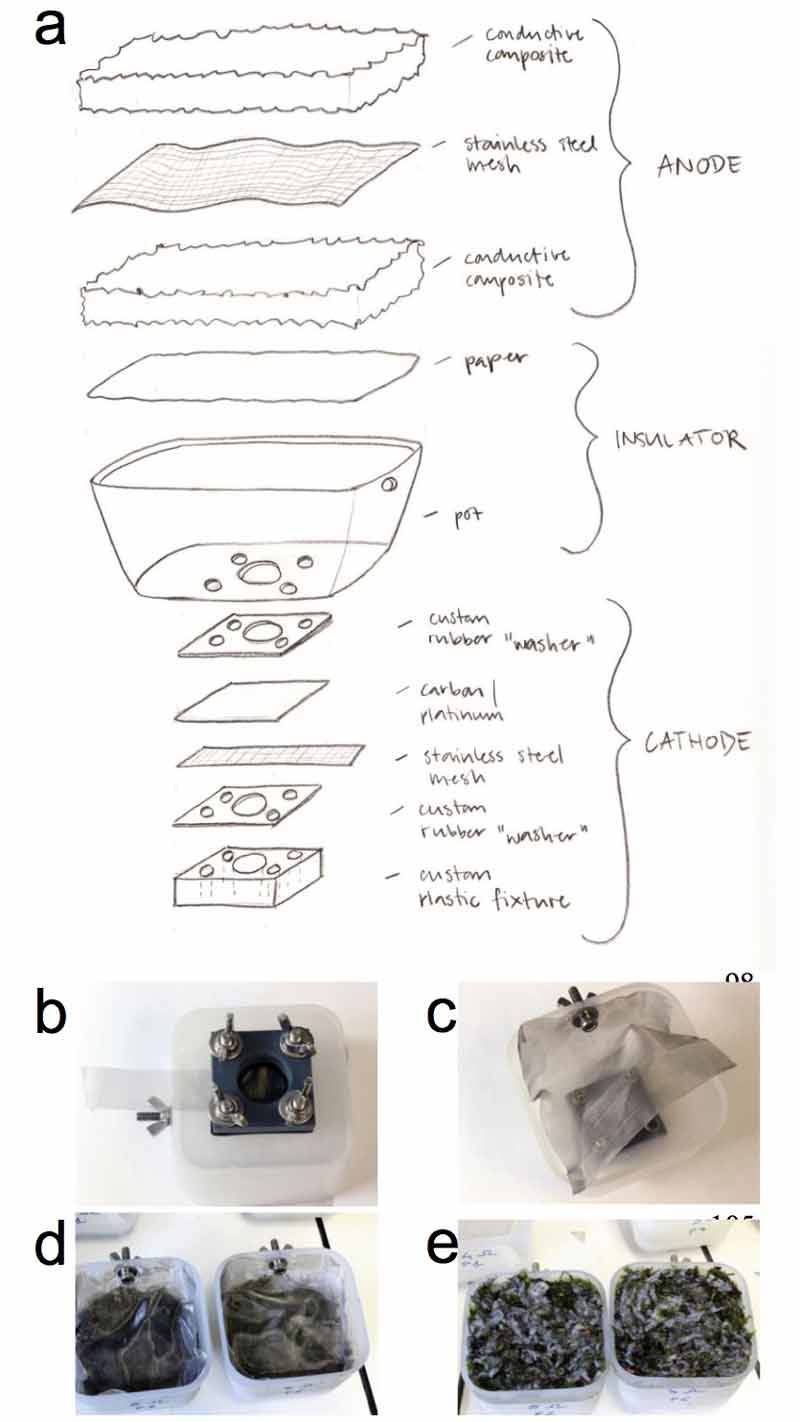

I would like to begin prototyping grow modules for Pure Imagination. The first challenge is setting up a plant microbial fuel cell system for generating electricity with moss.

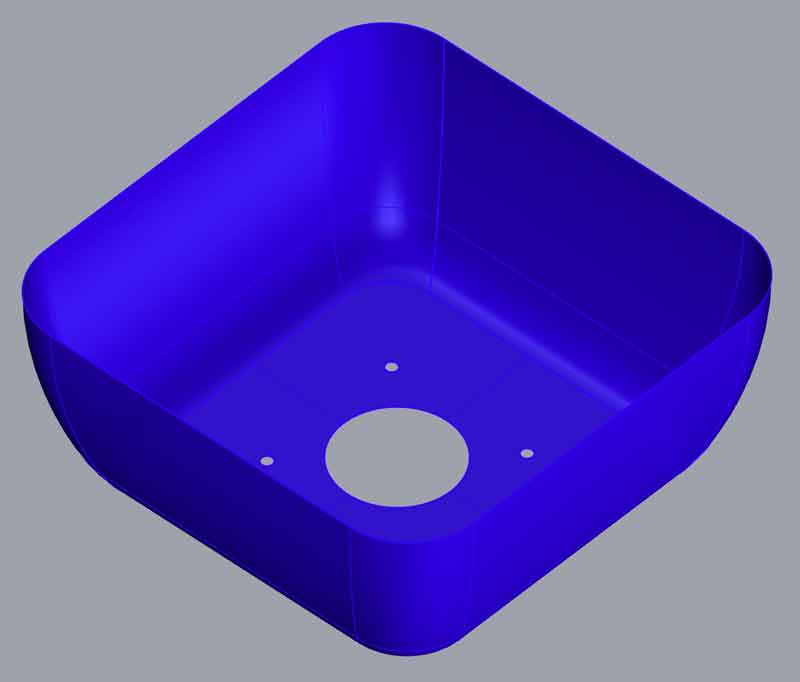

This work will heavily rely on the scientific research from Paolo Bombelli, et al. I thought I could cast this pot...

...and thinking how to do that with ooloo is tough. I think slip casting or vacuum forming would be the easiest route. I have experience vacuum forming and more, and would have some concern with the finishing that would need to be done after pulling a form for this object. If I slip cast a plaster mold with clay, the plaster has a long drying time and then each cast requires its own extended time plus glazing the inside to make it water resistant is extra effort.

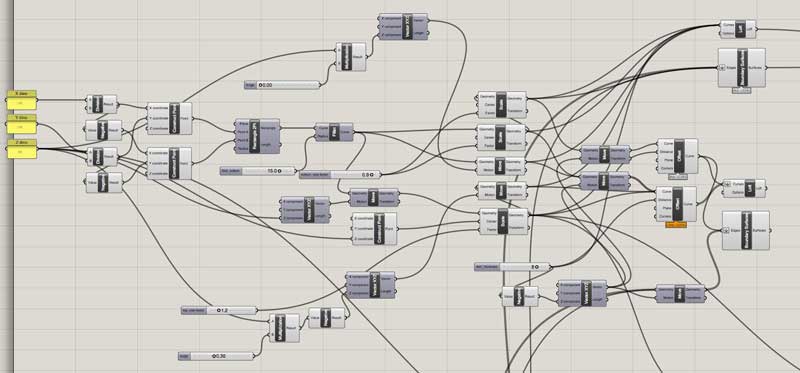

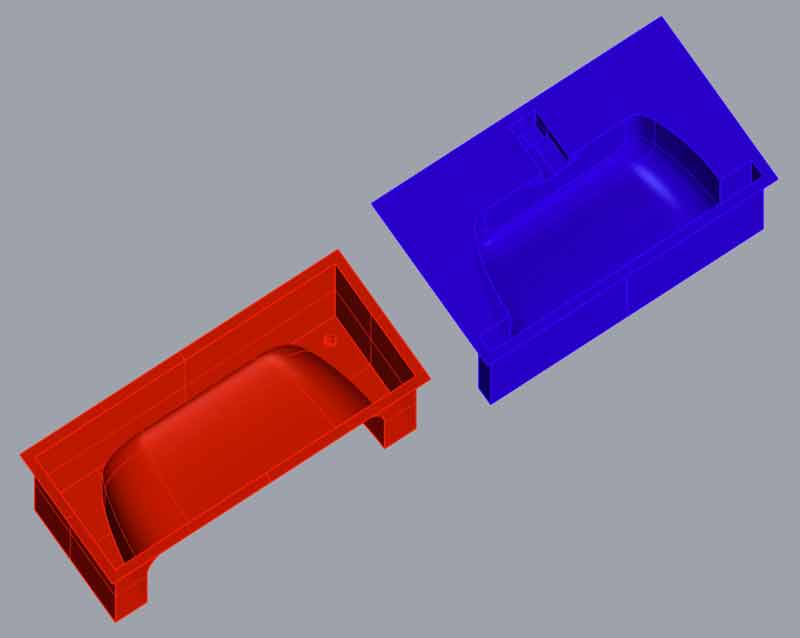

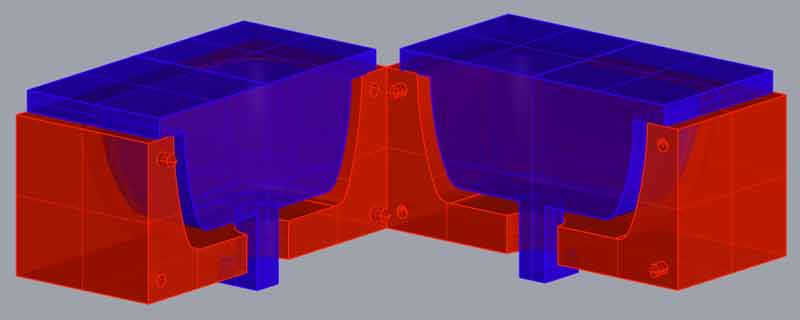

I came across a project by Nicolas Kisic Aguirre. He used four forms to make an sleeve. Maybe I can do something similar with two forms. First, grasshopper.

Next, a positive and a negative form which slot togther so they may float in space. Looking at this now, I think I can improve the slotting on the bottom, which is shown as the top in the second image. The blue section could wrap up the wall of the red a little to make a tighter seal.

Share this post...

« Previous post :: Prototyping the infinity axis

Now we have an operational prototype. Now we have a barely operational prototype. We decided I would focus on the mechanics of the second prototype. I wanted to improve several aspects of the first prototype. One, the robot should be easily portable, which I think works best if it can be easily dissambled and assembled. Two, the wheels do not balance the robot. Three, the effector and stage should be customized to the dimensions and requirements of this robot. In this section I will focus on the wheels, or the (Y) axis, the infinity axis. First, Saverio found this video...

Next post :: Star puzzle : Child's play? »

For my niece's birthday, I three-d printed a star puzzle. The toy however could never be dismantled after I muscled it together due to poor printer calibration on my part (a running theme in this blog). Further, duplicating the toy many times over comes with the time factor of three-d printing. Hint : slow. So, I thought it would be fun and good proving grounds to revisit this project in this exercise. And, the other day she asked if I had made the better version of her toy yet and gave me no leniancy for time spent building my first...